From form to function we can assist with all stages of the design process.

Industrial Design

Whether your company is starting at square one in defining basic product requirements and architecture or just looking to improve the aesthetics of an existing product, we can help you with innovative, groundbreaking ideas. We offer a full range of services required for all facets of the concept development process:

- Field and user research

- Competitive analysis

- Product configuration development

- Mockup construction

- Aesthetic development

- Design for manufacturing, service, and maintenance

- Concept illustration via manual and digital sketching

- Surface modeling

- Digital rendering

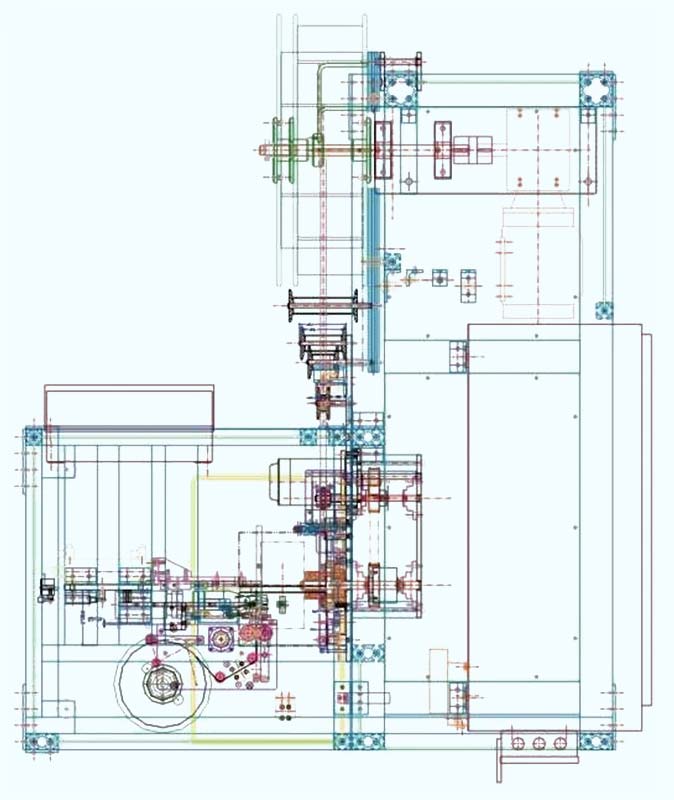

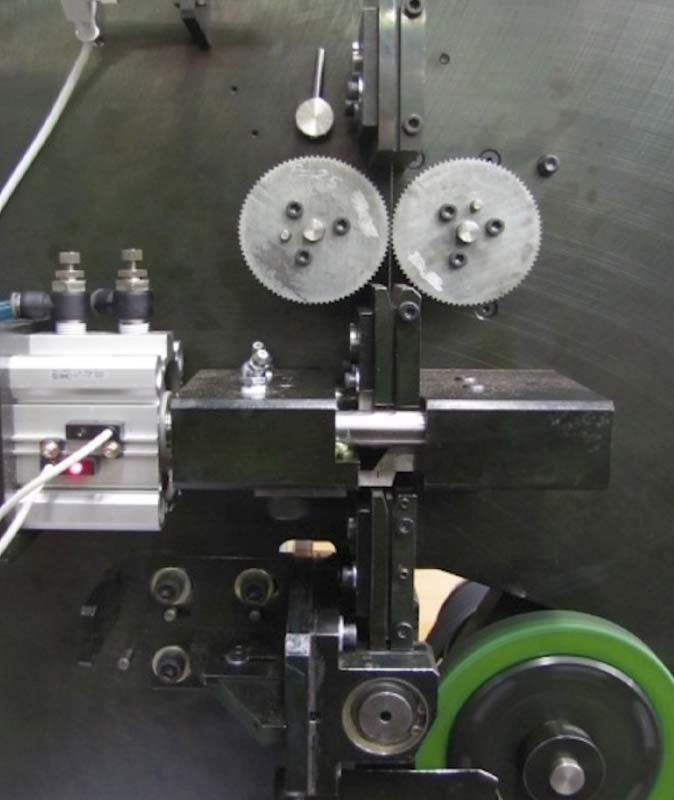

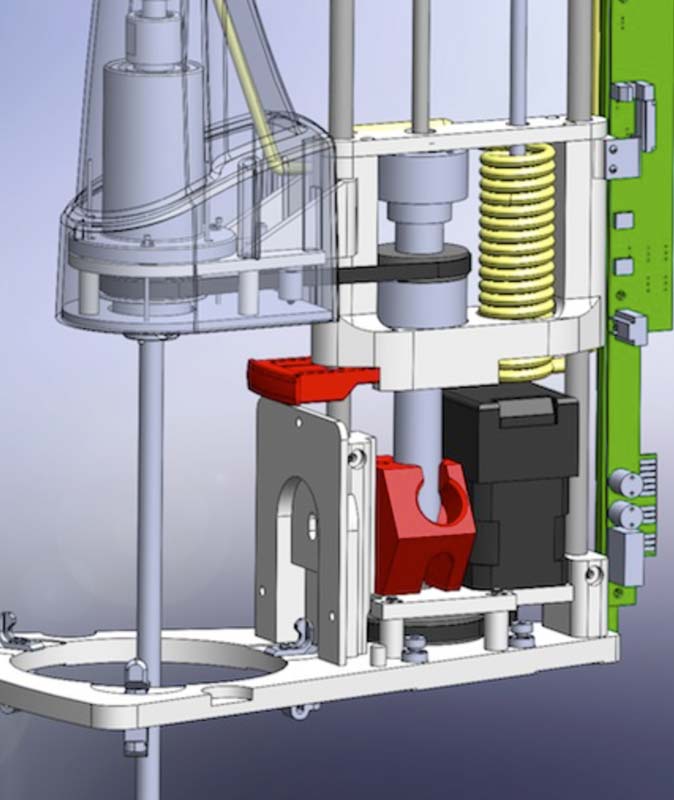

Mechanical Engineering

Phase One Design’s engineering expertise has been applied to products and systems ranging from medical instruments to assembly machinery and even large scale solar energy equipment. We pride ourselves in our knowledge of materials and processes appropriate to both small and large scale production. Our areas of expertise include:

- Product and mechanism architecture development

- Design for manufacturing and assembly

- Complex mechanism and drive system development

- Motion and position control system design

- Design for water and dust intrusion prevention

- Structural analysis

- Design testing and validation

Prototype Development

A soft foam prototype part and it’s mold. Produced in house.

Almost all of our projects require prototypes and in many cases we manage and expedite the prototyping process for our clients. While we don’t fabricate any prototypes in-house, we do rely on our network of service bureaus and shops to develop all of the parts necessary for assembly of fully functioning prototypes. These span a wide range of materials and processes including:

- 3D Printing, including FDM, SLA, DMLS, and Multi Jet Fusion

- CNC machining

- Sheet metal fabrication

- Water jet and laser cutting

- Plastic molding, including injection, structural foam, RIM, and pressure forming

- Metal casting, including die casting, investment, sand, and permanent mold.

- Urethane casting for prototypes

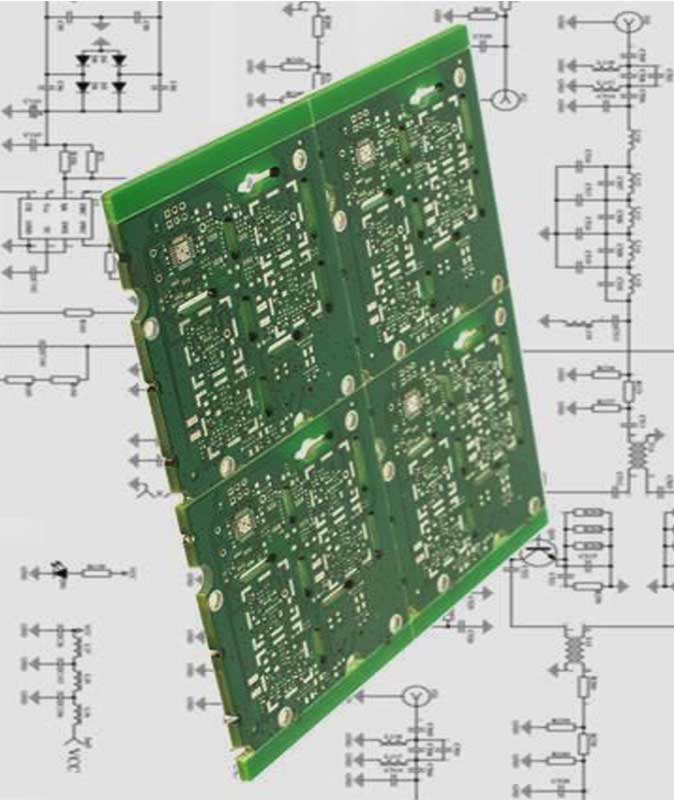

- Prototype and production PC board fabrication

Electrical Engineering

In many cases we are called upon to carry out electrical, electronic, and software solutions in conjunction with our aesthetic and mechanical design development. We offer high level electrical design expertise in the following areas:

- Microcontroller based product design and programming

- Through-hole and SMT printed circuit board (PCB) design and layout

- Stepper and Servo Motor based control system development

- Control Systems Integration

- Machine controls modernization and retro-fit

- RFI/EMI shielding design

- Vision and camera system design

Product Rendering

Not only does our CAD Rendering service allow clients to visualize products as they are developed, it also provides a time and cost effective alternative to traditional photography. We can provide marketing images as the product is developed, allowing our clients to publicize their products even before the final prototype is even complete.

- Interactive viewer for visual brand development, including color and material design explorations

- In context and in use composite renderings

- Line art and diagrams for manuals and patents

- Color matching/conversion, based of real world paint samples or Pantone Swatches, matched across print, web and screen

- Web based 360° interactive product views

- Animations including fly-throughs and motion studies

- Silhuetted images with masks/clipping paths and shadows on a separate layer or removed all together

Our Process

We work with start ups to large corporations and pride ourselves in developing long term relationships

that continue as our clients succeed and grow.

We can work with you to develop a visual brand language for your products